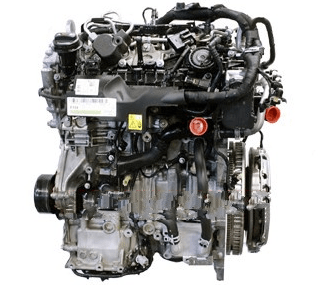

Mercedes M282 1.3L Engine Specs, Problems, Reliability. The Mercedes-Benz M282 is a 1.3-liter inline four-cylinder turbocharged and direct-injected engine established by Daimler in partnership with Renault-Nissan-Mitsubishi Alliance. The M282 engine made its launching in 2018. Nowadays, Mercedes uses this 1.3 L turbo-four in practically every front-wheel-drive model: A-Class, B-Class, CLA, GLA, and GLB. M282 1.3 engines are assembled in Germany at Daimler’s factory in Kolleda.

Renault and Nissan’s engines are produced at Alliance’s commercial facilities in Spain and United Kingdom. Renault brand names this engine as 1.3 TCe H5Ht (or TCe115, TCe160, tce140, and tce150), and Nissan gave the HR13DDT codename for it. Let’s take an extensive look at the Mercedes-Benz M282 engine style, the most common problems, reliability, and durability.

The M282 engine is constructed around an aluminum, open-deck style cylinder block established by Renault. The engine doesn’t have actually cast iron sleeves. Rather, there is a bore spray plasma finishing on cylinder walls. It is a thin layer of extremely difficult steel on the surface that enhances heat conductivity, lessens friction, and lowers the general weight of the engine.

The crankshaft and connecting rods are forged steel. The piston skirts have an Eco-Tough coating. It is a high wear-resistant, special graphite coating for enhanced friction. The engine block has oil squirters (piston cooling jets) that spray oil onto the underside of pistons to help get rid of heat. The oiling system features a variable displacement oil pump, which operates more efficiently with various capacities depending on engine requirements.

Table of Contents

Mercedes M282 1.3L Engine Specs, Problems, Reliability

The cylinder head was developed by Mercedes. It has a really uncommon triangular “Delta” design. This aluminum 16-valve cylinder head is slightly higher but much narrower and lighter than standard rectangle heads. This design likewise includes the semi-integrated consumption and exhaust manifolds. The consumption and exhaust camshafts come with variable cam-phasing (twin independent variable valve timing). The M282 utilizes a single-row timing chain which should last the whole life of the engine. The consumption and exhaust valves are actuated via finger follower-type rocker arms geared up with hydraulic guidance supports.

The Mercedes-Benz M282 features a direct fuel injection system. This is why the engine is equipped with a high-pressure fuel injection pump. It develops approximately 250 bar of fuel pressure inside a fuel circulation common rail. The high-pressure fuel pump is driven by a consumption camshaft via roller pushrod. The consumption camshaft has an additional 4-lobe cam for this function.

The common rail is gotten in touch with direct injectors, which spray gasoline straight into cylinders. The 6-hole injection nozzles are centrally located in the combustion chamber, supplying a effective and uniform combustion process. The crucial element of the M282 engine is a turbocharger. The engine includes a mono scroll turbocharger with a digitally managed wastegate. The exhaust manifold and turbocharger body are cast as one piece. An air-to-air intercooler lowers the temperature of compressed air before sending it to the consumption manifold.

In addition to the catalytic converter, the M282 engine has a particulate filter (OPF) as standard. Numerous enhancements were implemented for sound emission decrease. The consumption manifold includes a Helmholtz resonator, the catalytic converter has insulating seals, and its cover also reduces sound. Worth keeping in mind, the M282 engine is the very first four-cylinder Mercedes-Benz engine to feature a cylinder deactivation system (in connection with the 7G-DCT gearboxes). The motor can shut off the 3rd and 2nd cylinder in the partial load variety between 1,250 and 3,800 rpm.

Mercedes-Benz 1.3 L M282 Engine Problems and Reliability

Is the Mercedes-Benz M282 a good and dependable engine? We believe this 1.3 L I-4 turbo engine earns above-average remarks for reliability. Despite the fact that the engine is still brand-new for Mercedes, hundreds of thousands of Renault cars with 1.3 TCe engines are already on the roads all over the world. And it appears like this jointly-developed 1.3-liter turbocharged engine doesn’t have any major style flaws. There are some possible problems the 1.3 L M282 might run into.

There is the list of the most common Mercedes-Benz M282 engine problems understood to date:

- Extreme oil intake

- Carbon accumulation

We are categorizing excessive oil consumption as common, but it is in fact not so very common. Some owners reported progressive oil intake beginning already at low mileages. The cause of this issue was defective parts (oil rings, pistons). Likewise should take into account that this type of small-displacement turbo engine with direct fuel injection is vulnerable to take in oil under heavy loads more than the majority of naturally aspirated engines with a comparable level of efficiency. Injected fuel might wash out oil from the cylinder surface, which, by the way, appears like a mirror thanks to the NANOSLIDE procedure, and cause extensive wear of piston rings and cylinder walls. This may cause increased oil usage in some engines as they age. It is extremely crucial to utilize quality oil that fulfills all the needed specifications.

The 2nd problem is also related to the direct fuel injection system. Engines with direct fuel injection more or less experience carbon build-up on the intake valves and ports. Do not worry too much, many M282 engines will likely live their whole lives with excess carbon deposits. Only in some rare cases, the carbon accumulation might have a visible effect on performance.

Summarizing, the Mercedes-Benz M282 engine does provide an excellent balance of fuel economy, power, and reliability. We believe this little engine will last more than 160,000 miles (250,000 km). Keep in mind, appropriate upkeep and oil modifications are crucial to guaranteeing a trustworthy experience with the 1.3 M282 engine.

you must see more engine detail in here: Engine – US Cars News or you can see on wiki here

Mercedes M282 1.3L Engine Specs

| Manufacturer | Kolleda plant in Thuringia, Germany Beijing, China |

| Production years | 2018-present |

| Cylinder block material | Aluminum |

| Cylinder head material | Aluminum |

| Fuel type | Gasoline |

| Fuel system | Direct Injection |

| Configuration | Inline |

| Number of cylinders | 4 |

| Valves per cylinder | 4 |

| Valvetrain layout | DOHC |

| Bore, mm | 72.2 mm (2.84 in) |

| Stroke, mm | 81.3 mm (3.20 in) |

| Displacement, cc | 1,332 cc (81.3 cu in) |

| Type of internal combustion engine | Four-stroke, turbocharged |

| Compression Ratio | 10.6:1 |

| Power, hp | 109-163 hp (80-120 kW)/5,500 |

| Torque, lb ft | 133-184 lb ft (180-250 Nm)/ 1,375-4,000 |

| Engine weight | – |

| Firing order | 1-3-4-2 |

| Engine oil weight | SAE 0W-40, 5W-40 (229.51, 229.52, 229.61, 229.71) |

| Engine oil capacity, liter | 5.5 l (5.8 us qt) – with oil filter |

| Oil change interval, mile | 15,000 (25,000 km)/12 months – EU 10,000 (15,000 km)/12 months – USA |

| Applications | Mercedes-Benz A-Class, Mercedes-Benz B-Class, Mercedes-Benz CLA, Mercedes-Benz GLA-Class, Mercedes-Benz GLB-Class |